ADIABATIC SYSTEM

Adiabatic systems are standard products or accessories for Dry Coolers and Remote Condensers able to increase the relative humidity of the air passing through the exchanger, so as to decrease the temperature and increase heat exchange. This happens through the physical principle of the latent evaporation heat in which the water, by evaporating, absorbs heat from the air entering the heat exchanger, lowering its temperature.

HOW THEY WORK

The adiabatic saturation reduces the suction air temperature (respect to the ambient air) and therefore the efficiency of the heat exchanger increases. The adiabatic saturation temperature lowers – since evaporating water removes heat – though it is still higher than the dew temperature, as evaporation itself raises the partial pressure of water vapour. Thanks to Refrion's systems, the adiabatic saturation guarantees an increase of the relative humidity up to the whole saturation of the air (R.H.=100%)

EMERITUS®

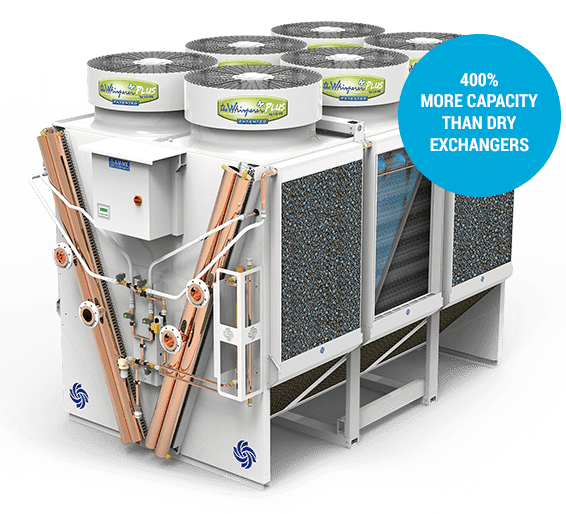

The new combined spray + adiabatic system

400% MORE CAPACITY THAN A DRY EXCHANGER

EMERITUS® is the latest innovation developed for the dry cooler, condenser and CO2 gas cooler families from LU-VE Exchangers.

Available for: HFC, NH3, Propane, CO2

Applications

The specific features of this product make it especially suitable for use in air conditioning and refrigeration. When EMERITUS® is applied to CO2 gas coolers, high system COP can be reached even during the hottest hours of the year, extending the geographical limits where trans-critical systems can becost-effectively constructed (the "CO2 equator").

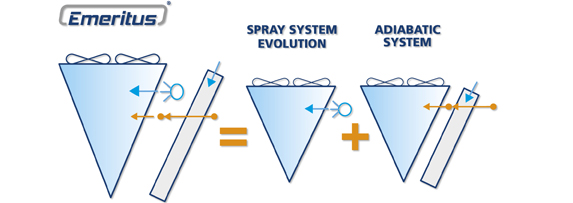

The operating principle of Emeritus®

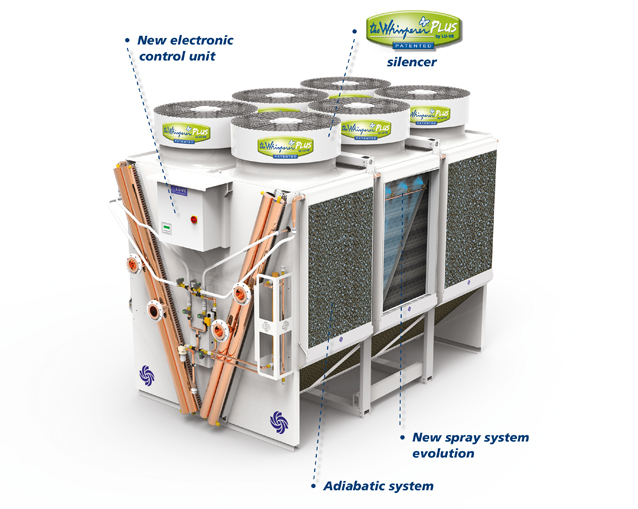

This new technological advance (patent pending) is the result of collaboration with the Polytechnic University of Milan and brings together the benefits of spray systems and adiabatic pre-cooling, all assisted by an advanced control system.

Intelligent Control System

with innovative, user-friendly functions. In addition to controlling electronic fans (EC), its sophisticated software memorizes the total operating hours of each ramp of the spray circuit and each adiabatic panel. Thanks to "logic of rotation", it selects which system should be activated, optimizing the numbers of hours of spray operation.

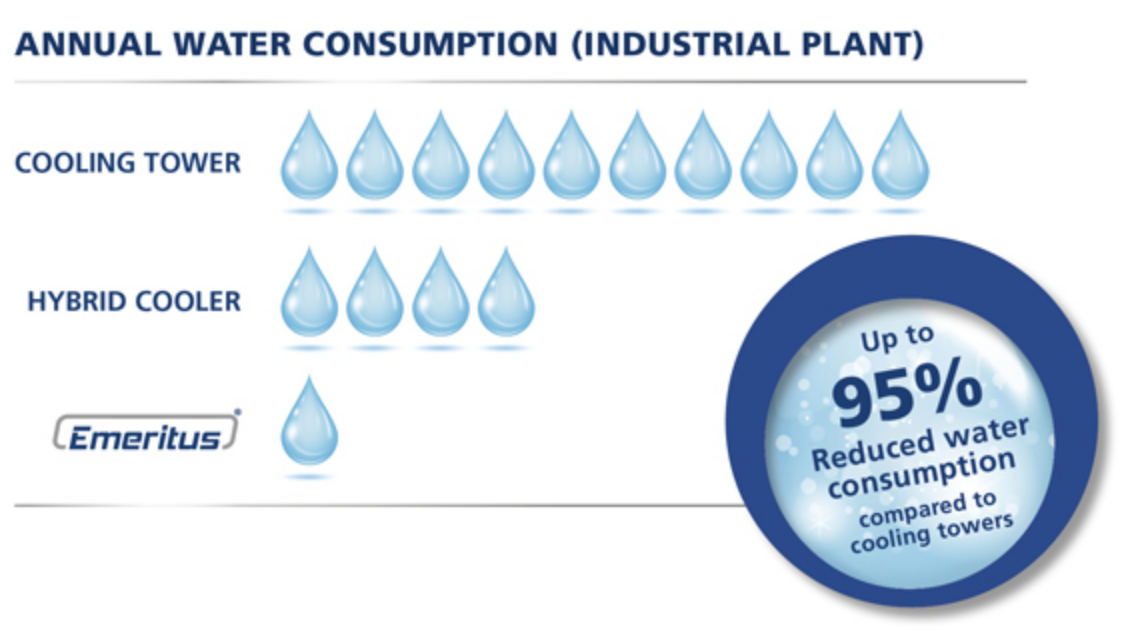

Reduced water consumption

Using the EMERITUS® dry coolers and condensers as alternatives to traditional condensers and evaporative towers brings significant advantages in terms of water consumption.