Mayekawa Manufacturing Company is one of the foremost world leaders in the manufacturing of freezing and compression technological. We are continually evolving, challenging and excelling beyond the expectations our markets set. The compression technology is continually improved and further developed to meet energy conservation requirements throughout the world. We continue with research and development into our compressors to not only meet the constantly changing requirements, but to open up new avenues and directions. We offer a wide array of compression that can utilize all types of refrigerants NH3, H2O, HC (Halocarbons) and CO2 allowing us to branch into all types of areas.

Single Stage

M II-series

Excellence in performance, durability, and high pressure resistance next-generation energy saving compressor

8M II

- High performance derived from new design

- Much Improved overhaul Intervals

- Compatible with natural (ammonia, propane) and fluorocarbon refrigerants

- Supports a wide range of pressure conditions

- Easy maintenance

WBHE-series

Our number one, large-size, single-stage series with a proven track record of trust and performance over 15,000 units in use worldwide

8WBHE

- New design with enhanced performance

- High-pressure design suitable for use in air-cooled condensing units for fluorocarbon refrigerants

- Compatible with natural (ammonia, propane) and fluorocarbon refrigerants

- Able to resiliently respond to load fluctuations

W Series

The Established Industry Standard

MYCOM's proven design in reciprocating compressors makes the W-series simple to service or overhaul at site; therefore, minimizing both overhaul cost and downtime. The W-series has time and again, proven its superiority in countless applications. It has set the standard for performance and durability in refrigeration for the past 20 years. Ease of operation and the simplicity of overhaul allow you to accurately determine your costs up front, cut down times to a minimum.

Benefits

- Ease of overhaul

- Long life with proper maintenance

- Optimum Vi at all times

- Simple oil cooling and simple head cooling

- Makes heat recovery easy

Brochures

HS-series

HS-series

Introducing a new high pressure series of compressors that use natural refrigerants and reduce energy consumption and CO2 emissions. When using the HS-series compressor in CO2 refrigeration, this compressor can also be used for defrosting of the system up to 20C, in addition to the refrigeration duty. The heat pump can produce hot water up to 95C with reduction of fossil fuel consumption such as oil and gas.

Benefits

- Internal relief valve

- Optimum Vi at all time

- Small capacity compressor

- High speed 1750 RPM

- Up to five steps of unloading

HK-series

HK-series

The HK-series is made for high pressure. This compressor is used in CO2 refrigeration systems and in HN3 heat pumps. When using the HK-series compressor in CO2 refrigeration, it is not necessary to foresee a separate defrosting compressor, as the basic refrigeration compressor can also be used in defrosting mode. HK-series compressor heat pumps contribute directly to important energy savings. The heat pump can produce hot water over 80C with significant reduction of fossil fuels such as gas and oil. HK-series compressors can be used in a wide range of pressures and speeds and will directly contribute in achieving your plant energy reduction plan.

Benefits

- Optimum Vi at all times

- High pressure compressor (50 bar)

- Up to five steps of unloading

Brochures

M Series

M Series

Mayekawa's latest in the reciprocating compressor range the M-series has quickly grown in popularity, exceeding our expectations to be our most efficient and robust model yet. With the power of Mayekawa's research and development department, we are pleased to introduce the new M-series compressor. This compressor was created to combat current soaring energy costs with the ability to reduce Kw consumption, while still providing the tonnage required. With efficiencies up to 20% better than conventional reciprocating compressors, and up to 30% better than mini screw compressors, the M-series has the power to reduce bottom line operating costs.

Benefits

- Greater efficiency with a screw capacity range

- Less BHP per ton

- Compact in design

- Precision design effortless overhaul

- 50% ~ 60% increase in run times between overhauls (Based on best case scenario)

Brochure

K Series

Multi-refrigerant small compressors one for multiple needs

Designed specifically for, but not limited to, halo-carbon refrigerants, the K-series compressor can offer a wide array of services from industrial to commercial purposes. Developed with the same high quality consistency MYCOM compressors are famous for, they continually offer a long life with low operational and maintenance costs. A lighter, smaller, and cost effective range of MYCOM compressors. All K-series and units, including chillers, will fit through a standard doorway (36″ x 80″).

Benefits

- Supports a wide range of operational speeds from 800 to 1800rpm

- Compatible with natural (ammonia) and fluorocarbon refrigerants

- High performance derived from new design

- Internal relief valve

- Optimum Vi at all times<

- Ease of operation

- Compact in design

- CFM 93.7 ~ 187.4

- Compatible with natural (ammonia, propane) and fluorocarbon refrigerants

- Capable of handling an extensive pressure range, including high pressure operating conditions such as those related to heat pumps

- Supports a wide range of operational speeds from 800 to 1800rpm

- Simplified package design

- Easy maintenance

WA-series

Suited for a wide range of applications. A medium-size, single-stage series with a proven track record of performance

<

6WA

<

6WA

- High pressure design suitable for use in air-cooled condensing units for fluorocarbon refrigerants

- Compatible with natural (ammonia, propane) and fluorocarbon refrigerants

- Able to resiliently respond to load fluctuations

HS-series

High pressure (60bar/870PSI) and high capacity compressor series compatible with natural refrigerants

6HS

- A newly designed compressor series which can generate up to 90℃ (194℉) hot water with ammonia heat pump systems

- 60bar (870PSI) high pressure design

- Flexibly contrebutes to the application with large scale systems

HK-series

Standard model of the high pressure (50bar/725PSI) compressor series compatible with natural refrigerants

6HK

- A compressor compatible with ammonia heat pump systems

- 50bar (725PSI) high pressure design

- Become the trusted model for many applications

Compound Two-Stage

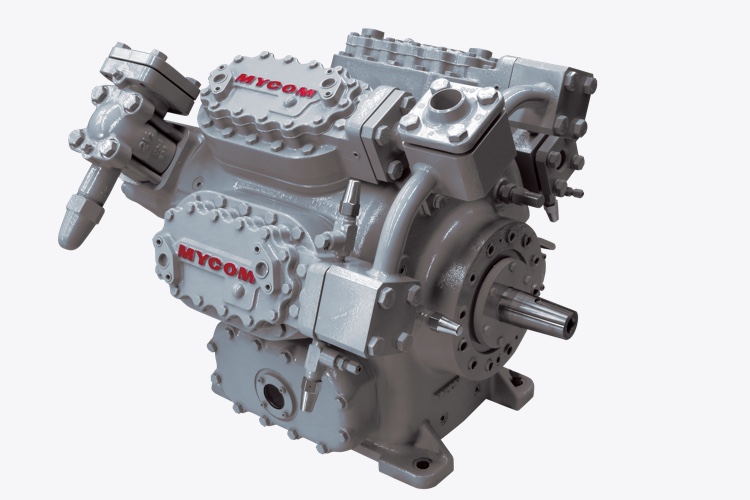

M II-series

Excellence in performance, durability, and high pressure resistance next-generation energy saving compressor

62M II

- This model serves large-scale deep freezing applications

- High performance derived from new design

- Much improved overhaul intervals

- Compatible with natural (ammonia, propane) and fluorocarbon refrigerants

- Easy maintenance

WBHE-series

Our number one, large-size, two-stage series with a proven track record of trust and performance over 15,000 units in use worldwide

62WBHE

- This model serves large-scale deep freezing applications

- High pressure design suitable for use in air-cooled condensing units for fluorocarbon refrigerants

- Compatible with natural (ammonia) and fluorocarbon refrigerants

- Able to resiliently respond to load fluctuations

WA Series

Suitable for a wide range of applications. A medium-sized, two-stage series boasting an impressive track record

62WA

- High pressure design suitable for use in air-cooled condensing units for fluorocarbon refrigerants

- Compatible with natural (ammonia) and fluorocarbon refrigerants

- Able to resiliently respond to load fluctuations

K-series

Multi-refrigerant small compressors one for multiple needs

62K

- High performance derived from new design

- Compatible with natural (ammonia) and fluorocarbon refrigerants

- Supports a wide range of operational speeds from 800 to 1800rpm

- Simplified package design

MYCore RC100

MyCore RC100 – control panel for reciprocating compressor units

A control panel for reciprocating and small screw compressor units. This control panel provides optimized control for the entire compressor unit, including capacity control, VFD speed control, and alarm monitoring.

MyCore-RC100

- Equipped with data logging function

- Communication with the host PLC is possible through Modbus protocol

- Multilingual support