PACKAGED PUMPING SYSTEMS

Basic or complex, we can offer a complete solution for your packaged pumping system requirements. Each pumping system is designed to do a specific pumping job. Precisely matched pumps, valves, motors, and controls are engineered for long life and trouble free operation. We have built a reputation on pumping systems that offer reliability, durability, and service that is second to none.

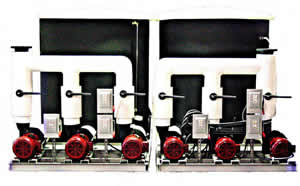

COOLING TOWER PUMPING SYSTEMS

CTPS system provides central pumping needs and control of cooling tower water in a pre-engineered package, matched to your process operation demands.

CTPS units are capable of handling capabilities from 100 to 500 nominal tons. Tempest also designs and manufactures specialized equipment for non-standard applications.

Standard features

- Heavy duty welded steel frame

- Stainless steel reservoir

- Site glass

- Automatic level control

- Tower fan & pump cycling thermostat

- Pressure Gauges

- Drain Valve

- Lug mount butterfly valves

- Centrifugal close coupled pump

- Control panel mounted & wired

Optional features

- Stand by pumps

- High temperature alarm

- TEFC motors

- Armaflex insulation

- VFD’s

- Reservoirs

- Mild steel epoxy coated

- Polypropylene

- Reservoir cover

- Mounted auxiliaries

- Filters

- Chemical free water treatment systems

CHILLER PUMPING SYSTEMS

A complete line of chiller pumping systems ranging from a simple tank with a single pump to a 1200-gallon hot/cold tank with multiple pumps. Hot/cold tanks are fitted with two pumps, one for the process and one to recirculate to the fluid cooler. The standby pump option is piped to serve as a backup for the process or recirculating pump.

Capacities range from 25 to 200 nominal tons. We can also design and manufacture specialized equipment for non-standard applications.

Standard features

- Heavy duty welded steel frame

- Stainless steel reservoir

- Reservoir cover

- Armaflex insulation

- Site Glass

- Fill valve

- Drain valve

- Lug mounted butterfly valves

- Centrifugal close coupled pumps

- Control panel mounted & wired

Optional Features

- Standby pumps

- TEFC motors

- Reservoirs

- Mild steel epoxy coated

- Polypropylene

DEIONIZED WATER SYSTEMS

DWS large industrial DI water systems are ideal for central plant pumping stations. Our custom designed systems are built to your exact specifications. Constructed on heavy-duty welded steel frames, with 316SS reservoirs that have capacities from 500 to 1200 gallons. Fully welded 316SS piping systems, flanged components, and stainless steel duplex, centrifugal type pumps.

Options include

- Ultra pure PVC pipe construction up to 6”

- Ultraviolet sterilizer

- FRP-jacketed polyethylene tanks

- Coupon rack

- Chemical pot feeder

- Water cartridge filter

- Process filter

- Armaflex insulation

- PLC controls