COPPER BRAZED PLATE HEAT EXCHANGERS

The Alfa Laval CB range of brazed plate heat exchangers feature efficient heat transfer with an extremely small footprint, making them ideal for demanding installations where space is at a premium. The CB range is used in HVAC heating/cooling, refrigeration, process heating/cooling, oil cooling, solar heating and many other applications.

Copper brazed plate heat exchangers provide efficient heat transfer with a small footprint. They are maintenance free, provide a long service lifetime and can withstand high temperatures and extremely high design pressures. They are used in a range of duties including cooling, heating, evaporation and condensing. For complete product range see below

The CB range of brazed plate heat exchangers has numerous advantages over traditional heat exchangers in both industrial, HVAC and refrigeration installations. The exceptional heat transfer efficiency makes all CB units very compact. As a result, they can tackle large-capacity duties even though there is only limited installation space available.

The brazed construction also does away with gaskets, making CB units ideal in applications where temperatures and/or pressures are high. Examples include district heating and a wide range of heating, cooling and tap water solutions.

Alfa Laval is the world's leading manufacturer of brazed plate heat exchangers. This means solid experience in designing units that withstand high-pressure and high-temperature conditions, and in coping effectively with the structural stresses that results from these. Units in the CB range are available in many different sizes and capacities, with varying plate patterns and connections for particular duties and performance specifications. CB units can be configured as single-pass, dual-pass or multi-pass installations, according to project requirements.

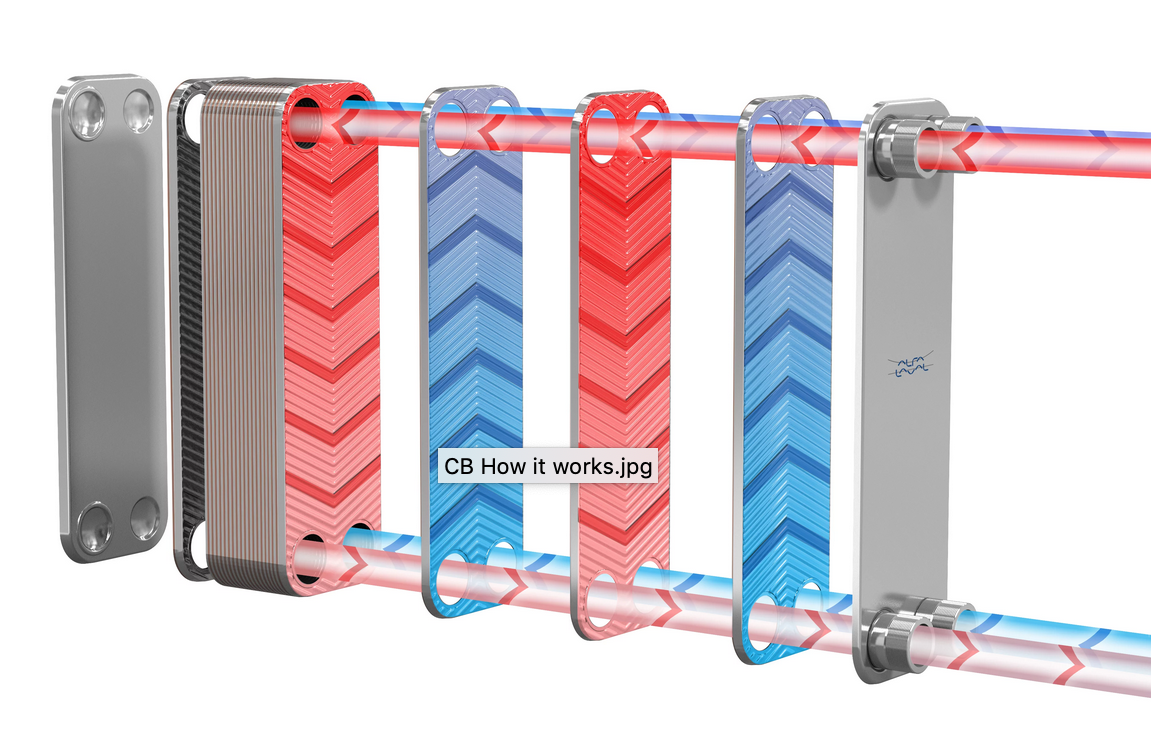

How It Works

How It Works

In Copper Brazed (CB) heat exchangers, the surfaces used to provide heat transfer from one medium to the other are thin, corrugated stainless steel plates stacked on top of each other. The two media are sealed within the plate pack by a brazed copper seal around the edge of the plates. This results in a heat exchanger that – unlike traditional designs – consists solely of surfaces which actively contribute to heat transfer, resulting in significant increases in overall efficiency.

The channels formed between the plates and corner ports are arranged so that the media flow through alternate channels – always in a counter-current flow pattern in order to achieve the most efficient heat transfer.

The contact points between the plates are also brazed, helping to withstand the effects of high pressures and high temperatures. Pressure peaks and rapid temperature cause substantial physical stresses within the materials, and Alfa Laval research has focused on the details of these phenomena in order to ensure designs that are extremely resilient and provide a long service life.