BRAZED PLATE HEAT EXCHANGERS

Alfa Laval copper-brazed plate heat exchangers are a compact, efficient and maintenance-free solution for heating, cooling, evaporation and condensing in numerous applications. Each unit is designed for duty optimization, with a range of unique features that ensure both superior thermal performance and maximum reliability. This enables the longest possible service life – even under conditions with extremely high design pressures.

Alfa Laval AC line of brazed plate heat exchangers provide efficient heat transfer with a small footprint. They are specifically developed to work in air conditioning, refrigeration, chillers and heat pump applications.

Efficient heat transfer with an extremely small footprint, making them ideal for demanding installations where space is at a premium, Alfa Laval brazed plate heat exchangers forming a self-contained unit that can handle both high pressures and high temperatures resulting in significant increases in overall efficiency.

Brazed plate heat exchangers are widely used in refrigeration plants. They are normally used to transfer heat from the refrigerant – the primary fluid – and from water or brine as the secondary fluid.

Units in the Alfa Laval AC series of copper-brazed heat exchangers are mainly used as:

- Evaporators for dry expansion and cooling water

- Condensers for rejecting or recovering heat to water

- Economizers for cooling liquid refrigerant and super-heating vapor refrigerant.

They can also be used as:

- Sub-coolers to cool liquid refrigerants using well water

- Intermediate heat exchangers in the absorption cycle, to preheat the diluted solution or to pre-cool the concentrated solution.

Uses

Air Conditioning

Beverage

Commercial Refrigeration

HOW IT WORKS

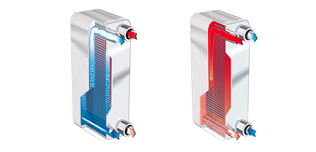

Brazed plate heat exchangers used for HVAC applications normally use a parallel flow to achieve the most efficient heat transfer. In a single-pass design, all the connections are located on one side of the heat exchanger, making installation very easy.

Alternate Channel Pattern

When used as an evaporator, the channels formed between the corrugated plates and corners are arranged so the two media flow through alternate channels, always in opposite directions (counter-current flow). The two-phase refrigerant (vapour + liquid) enters at the bottom left of the unit. The vapour quality depends on operating conditions in the refrigeration plant.

Dry Expansion

Evaporation of the liquid phase takes place inside the channels. Some degree of superheating is always required – hence the process being called “dry expansion”. The dark blue and light blue arrows show the location of the refrigerant connections. The water (brine) to be cooled flows counter-currently in the opposite channel; the dark and light red arrows show where the water (brine) connections are.

AC Line as Condenser

When used as a condenser, the main components are still the same as for the evaporator. The refrigerant enters at the top left as a hot gas and starts to condense on the surface of the channels. Once fully condensed, it is then subcooled slightly, in a process called “free condensation”. The dark and light blue arrows show the location of the brine connections. The refrigerant flows counter-currently in the opposite channel and is cooled. The dark and light red arrows show where the refrigerant connections are.

Brazed plate heat exchangers are widely used in refrigeration plants. They are normally used to transfer heat from the refrigerant – the primary fluid – and from water or brine as the secondary fluid.

Units in the Alfa Laval AC line of copper-brazed heat exchangers are mainly used as:

-

Evaporators for dry expansion and cooling water

-

Condensers for rejecting or recovering heat to water

-

Economizers for cooling liquid refrigerant and super-heating vapour refrigerant.

They can also be used as:

-

Sub-coolers to cool liquid refrigerants using well water

-

Intermediate heat exchangers in the absorption cycle, to preheat the diluted solution or to pre-cool the concentrated solution.