INDUSTRIAL UNIT COOLER EVAPORATORS

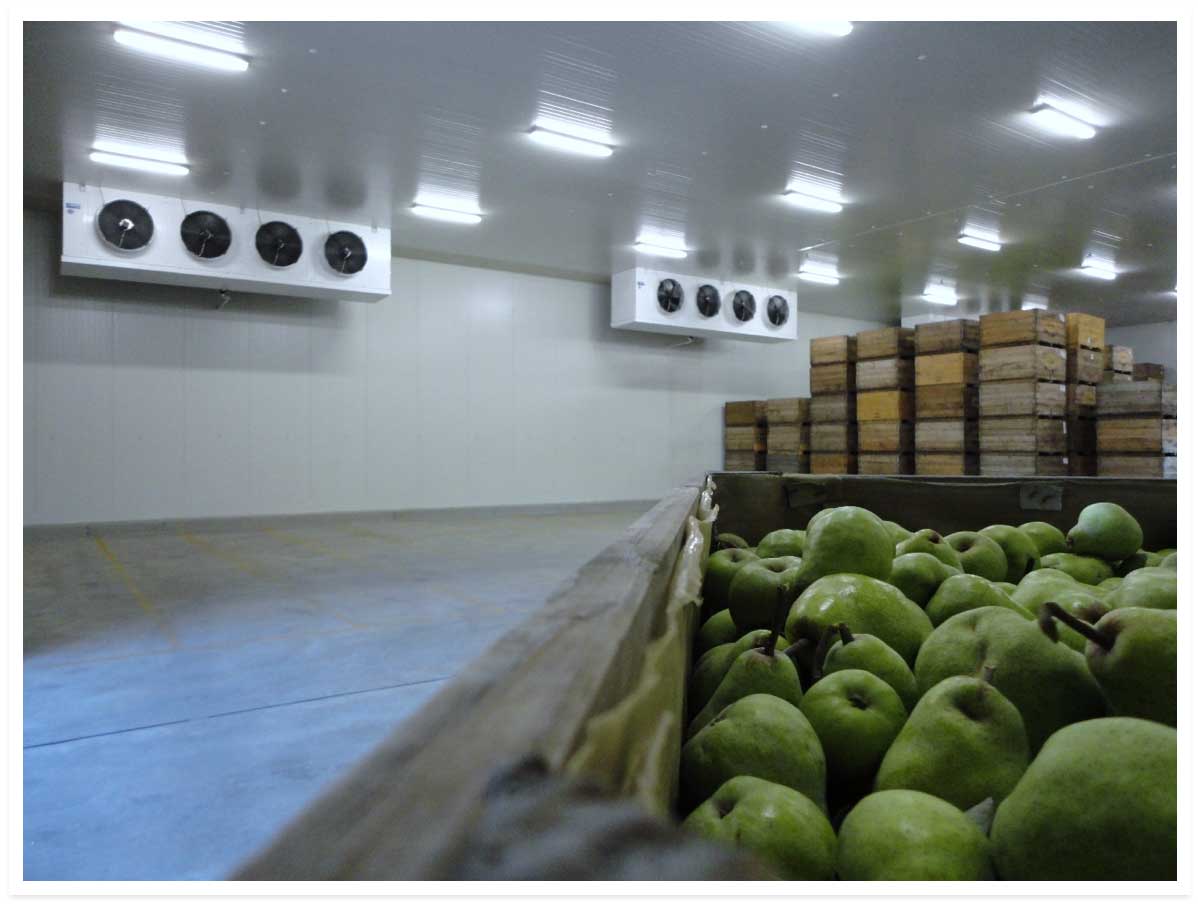

LU-VE has a vast range of standard industrial unit coolers which can satisfy most industrial refrigeration installation requirements. One of LU-VE's strengths is its ability to help both the refrigeration engineer and the designer to choose the best product for a specific refrigeration installation. The industrial unit coolers, designed for the conservation of fresh or frozen goods and flash freezing/temperature reduction, are subdivided into:

All the ranges have these special characteristics of size and function

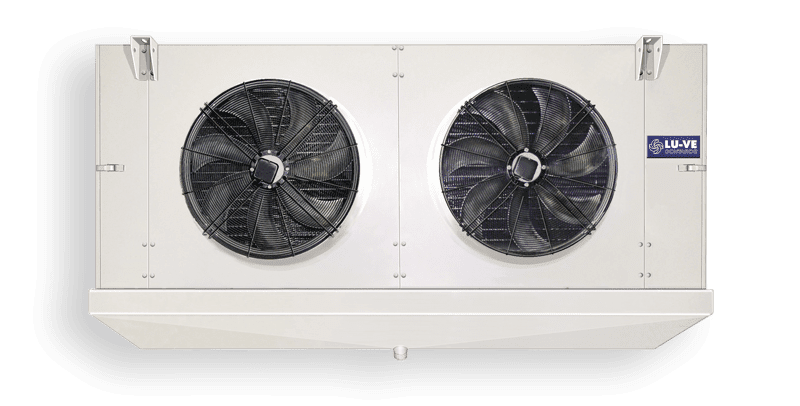

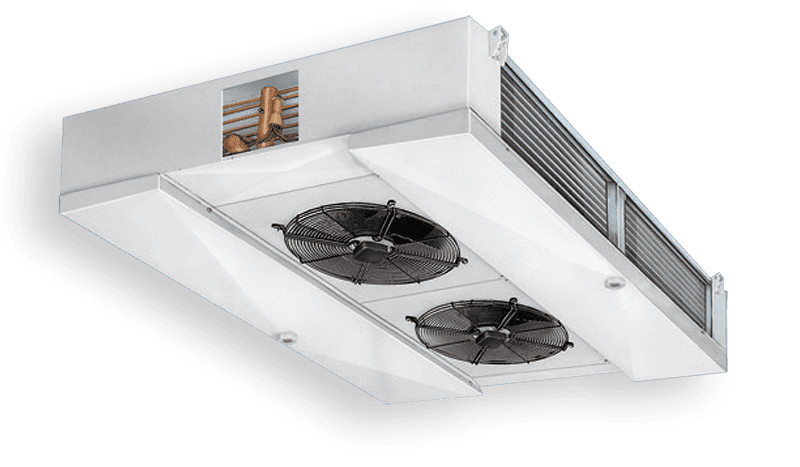

Dual discharge industrial unit coolers CDH

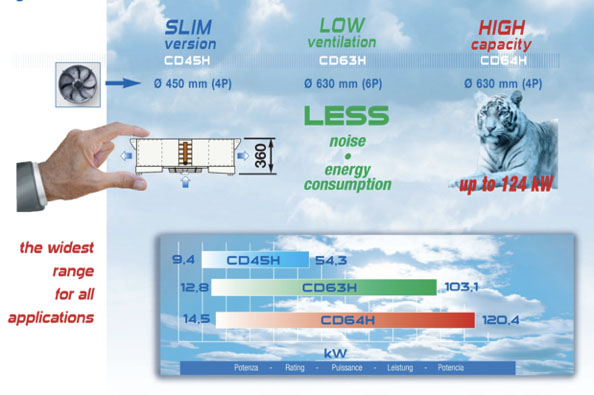

SLIM Version – CD45H – Ø 450mm (4P)

LOW Ventilation – CDH63H – Ø 630mm (6P)

HIGH Capacity – CD64H – Ø 630mm (4P)

Fin spacing: 4,5 mm – 6 mm – 7,5 mm – 10 mm

From 1 to 4 fans

112 models from 8,6 to 125,1 kW

Key Features

Key Features

- Enlarged range

- Alignment with the CS technology

- Improved quality casing and design

Main features

TURBOCOIL® heat exchanger

The heat exchanger Turbocoil®, each coil is constructed using a special internal ripple finned tube with staggered rows, equipped with the new Turbofin 3, is characterised by an optimal ratio between secondary fin surface and primary surface of the tubes ensuring very high unitary capacities.

Industrial evaporator for cold rooms CHS-LHS

Fin space: 4.5 mm – 6 mm – 7.5 mm – 10 mm – 12 mm

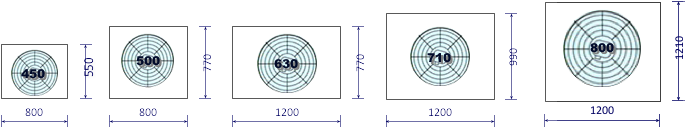

From 1 to 4 fans, Ø 450 – 500 – 630 – 710 – 800 mm

Low noise operation and reduced energy consumption

10 ranges from 7 to 216 kW

Large Hitec Surface available with in-line row pattern

Main features n Industrial evaporator for cold rooms CHS-LHS

Heat Exchanger

CHS – Compact Hitec Surface

TURBOFIN® 3 heat exchanger

The heat exchanger with internally grooved tubes and staggered rows, suitable for both positive and negative temperature applications for the conservation of products with low humidity content, or packed products.

LHS – Large Hitec Surface

TURBOFIN® 4 heat exchanger

The heat exchanger with internally grooved tubes and in-line rows, featuring a high ratio between the secondary fin surface and the primary tube surface, suitable for conservation cold rooms for products with high humidity content, and for freezing.

Fin spacing and best use

Fin spacing and best use

Range 4 – 4.5 mm: conservation at positive temperature

Range 6 – 6,0 mm: conservation at positive temperature

Range 7 – 7.5 mm: conservation at negative temperature

Range 10 – 10 mm: freezing and conservation at negative temperature

Range 12 – 12 mm: freezing

DEFROST

N = air defrost (TC> 2°C)

E = electric defrost (TC> -35°C)

SB = water spray defrost (TC> -2°C)

G = hot gas defrost for coil and electric defrost in the drain tray (TC> -35°C)

GB = hot gas defrost for coil and drain tray (TC> -35°C)

CASING

Zinc coated steel casing with corrosion-resistent powder coating finish

CS80 Industrial evaporator for cold rooms range CHS-LHS

High Range Flexibility5 modules! 5 fan standard diameters

- 1 – 6 fans

- 5 fin spacings – 2 geometries

- More than 816 standard models

- Freon – Glycol – Ammonia – Hot gas defrost – Water Defrost – Accessories

Main features Fast Freezer Special Evaporators

TURBOFIN® 4 heat exchanger

The heat exchanger with internally grooved tubes and in-line rows, featuring a high ratio between the secondary fin surface and the primary tube surface, suitable for all design requirements for the refrigeration and tunnel freezing of food products.

Defrost

Defrost

N = air defrost (TC> 2°C)

E = electric defrost (TC> -35°C)

SB = water spray defrost (TC> -2°C)

G = hot gas defrost for coil and electric defrost in the drain tray (TC> -35°C)

GB = hot gas defrost for coil and drain tray (TC> -35°C)

CASING

Zinc coated steel casing with corrosion-resistent powder coating finish.

Fan diameter 500 and 630 mm From 2 to 8 fans

Capacity: from 10 to 170 kW

https://youtu.be/dPPU67MgRHY

Industrial unit coolers for ammonia operation LSA-CSA

Fin spacing: 4.5 mm – 6 mm – 7.5 mm – 10 mm – 12 mm

From 1 to 6 fans, Ø 450 – 500 – 630 – 800 mm

Low noise operation and reduced energy consumption

392 models from 9 to 240 kW

Main features Industrial unit coolers for ammonia operation LSA-CSA

Heat Exchanger

Heat Exchanger

CHS – Compact Hitec Surface

TURBOFIN® 3 heat exchanger with stainless steel tubes and staggered rows, suitable for both positive and negative temperature applications for the conservation of products with low humidity content, or packed products.

LHS – Large Hitec Surface

TURBOFIN® 4 heat exchanger with stainless steel tubes and in-line rows, featuring a high ratio between the secondary fin surface and the primary tube surface, suitable for conservation cold rooms for products with high humidity content, and for freezing.

Fin spacing and best use

Range 4 – 4.5 mm: conservation at positive temperature

Range 6 – 6.0 mm: conservation at positive temperature

Range 7 – 7.5 mm: conservation at negative temperature

Range 10 – 10 mm: freezing and conservation at negative temperature

Range 12 – 12 mm: freezing

Defrost

N = air defrost (TC> 2°C)

E = electric defrost (TC> -35°C)

SB = water spray defrost (TC> -2°C)

G = hot gas defrost for coil and electric defrost in the drain tray (TC> -35°C)

GB = hot gas defrost for coil and drain tray (TC> -35°C)

https://youtu.be/bEbc7B5muxA